Inventory Management Things To Know Before You Buy

The smart Trick of Inventory Management That Nobody is Discussing

Table of ContentsFascination About Inventory ManagementInventory Management Can Be Fun For EveryoneThe Ultimate Guide To Inventory ManagementInventory Management Fundamentals Explained

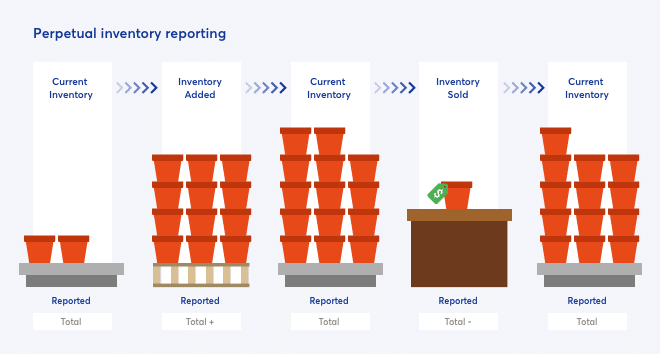

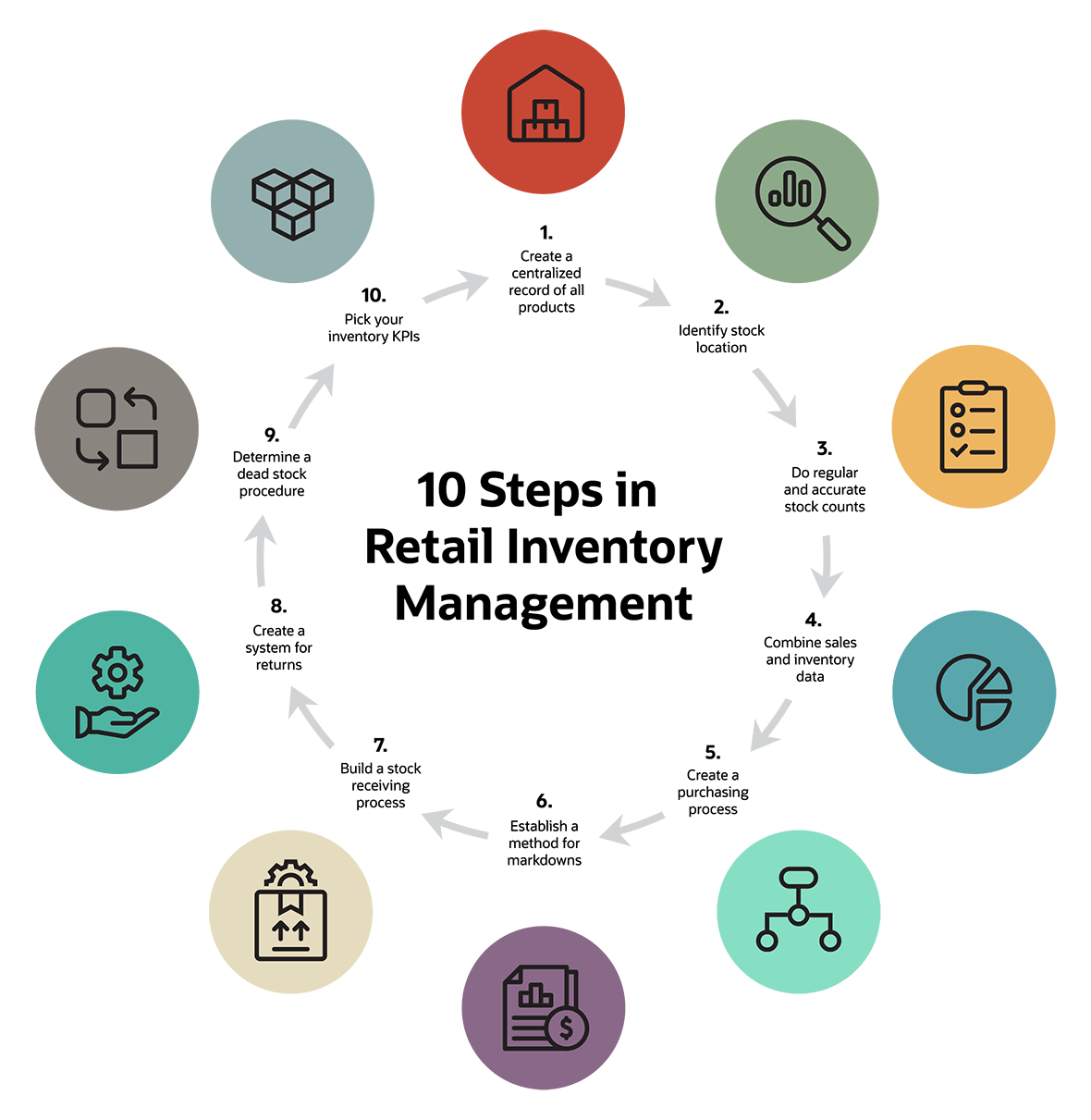

There are two major techniques of keeping an eye on supply: regular and also perpetual. The major distinction between these is exactly how usually data is updated. No matter of how usually you track supply, you may desire to use one of the adhering to stock monitoring methods: ABC Analysis, ABC (Always Better Control) Analysis is supply management that separates various items right into three groups based on rates as well as is divided into groups A, B, or C.The products in the B group are reasonably less expensive compared to the A classification. And the C classification has the least expensive items of all 3. EOQ Model, Economic Order Quantity is a strategy made use of for planning and also purchasing an order quantity. It includes making a decision regarding the amount of stock that must be put in supply at any kind of offered time. Inventory Management.

FSN Technique, This technique of inventory control refers to the procedure of monitoring all the items of stock that are not made use of often or are not required regularly. They are then categorized into 3 different classifications: fast-moving supply, slow-moving inventory, as well as non-moving supply. JIT Approach, Simply In Time stock control is a process made use of by manufacturers to control their supply degrees.

See This Report about Inventory Management

VED Evaluation, VED is a technique utilized by companies to regulate their inventory. The high level of inventory that is needed for production typically warrants the reduced inventory for those parts.

Wrike is a job management service that can aid you do exactly that. With Wrike's product administration tools, you can take care of every one of your product team's tasks in one location as well as obtain one of the most out of every task. Wrike's product launch automation helps speed up item launches with a streamlined strategy.

Little Known Questions About Inventory Management.

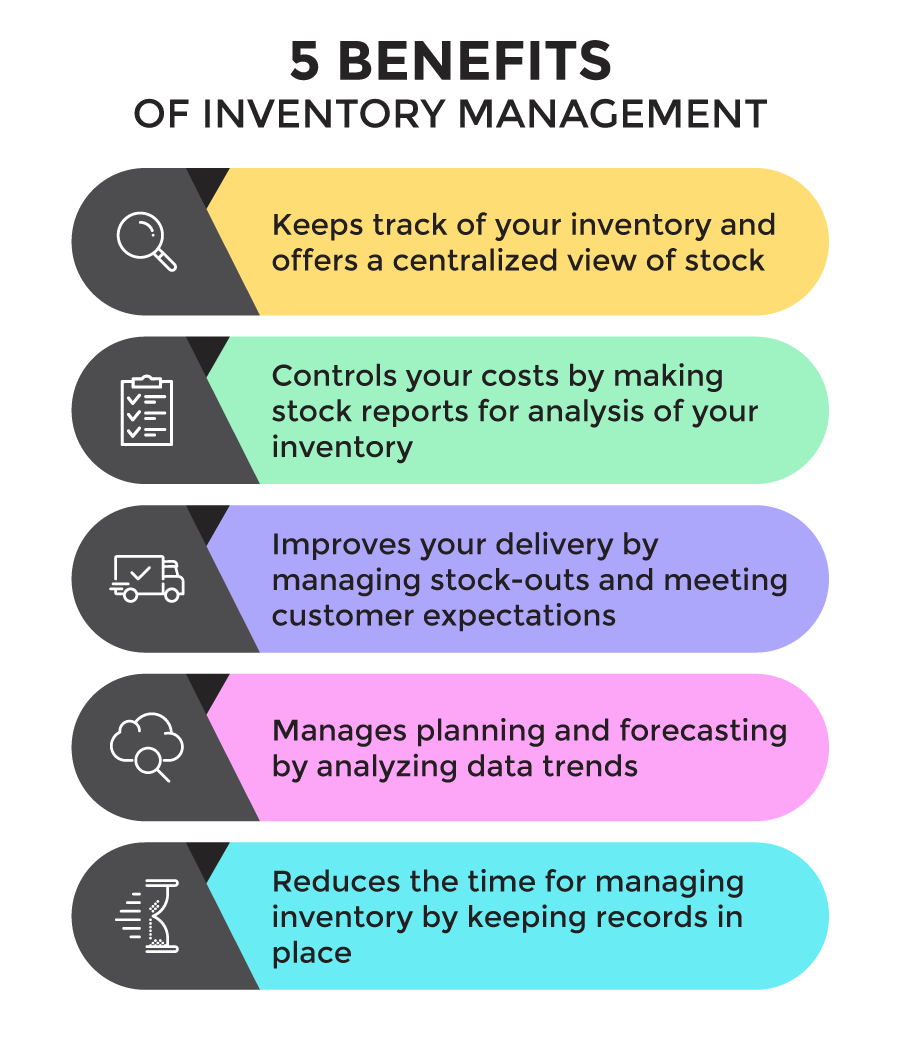

Supply management refers to the process of buying, saving, making use of, as well as marketing a firm's supply. This consists of the administration of basic materials, parts, and also my latest blog post finished products, along with warehousing and also handling of such things. There are different types of stock management, each with its pros and disadvantages, depending upon a business's requirements.

Supply administration attempts to efficiently streamline stocks to avoid both excess and also scarcities. Four significant stock administration techniques consist of just-in-time administration (JIT), materials demand planning (MRP), financial order quantity (EOQ), and also days sales of inventory (DSI). There are pros and also cons to every of the approaches, assessed listed below. A business's stock is one of its most important assets.

A scarcity of inventory when as well as where it's needed can be very damaging. At the very same time, inventory can be thought of as an obligation (if not in a bookkeeping feeling).

Small companies will frequently maintain track of supply manually and determine the reorder factors and quantities using spread sheet (Excel) formulas.

Little Known Questions About Inventory Management.

Appropriate stock management approaches vary relying on the industry. An oil depot is able to keep big amounts of stock for extensive time periods, enabling it to await need to pick up. While keeping oil is expensive and also riskya fire in the U.K. in 2005 led to countless extra pounds in damage and also finesthere is no danger that the supply will certainly ruin or head out of design.

For firms with check complex supply chains and also manufacturing procedures, balancing the dangers of supply excess and also lacks is especially challenging. To accomplish these equilibriums, firms have created numerous methods for inventory administration, consisting of just-in-time (JIT) as well as materials requirement planning (MRP). Some firms, such as monetary solutions companies, do not have physical inventory therefore needs to depend on solution process management.

Inventory has to be physically counted or gauged prior to it can be placed on a balance sheet. Ended up items are completed items conveniently available for sale you could try here to a firm's customers. Depending on the kind of service or item being examined, a firm will make use of numerous inventory monitoring methods.